Which Chemical Pump Is More Suitable For Electroplating Waste

TIME:2024-06-04 Author:admin Views:

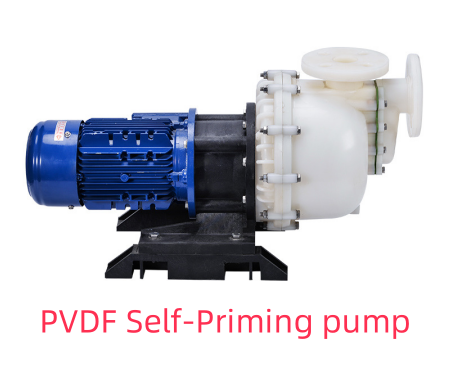

1. The sewage lifting pumps required for sedimentation tank pretreatment include PVDF self-priming pumps and PVDF magnetic pumps.

Process introduction: The main purpose of pretreatment in the sedimentation tank is to precipitate the metal residue in the electroplating wastewater through natural sedimentation or centrifugal sedimentation to facilitate the next step of treatment.

On the one hand, a sewage lift pump is required to transport the wastewater generated in the electroplating plant to the settling tank of the treatment plant. Since wastewater is relatively acidic, the transportation pipelines and sewage lift pumps are required to have strong acid corrosion resistance. Moreover, the sealing performance of the pipeline needs to be ensured to prevent wastewater from leaking and polluting the environment;

On the other hand, after the wastewater enters the sedimentation tank, it is generally settled by natural sedimentation method. Although this method consumes less energy, the sedimentation rate is relatively slow. When the pressure of electroplating wastewater treatment is high, centrifugal sedimentation method is generally used. The advantage of this method is that the processing speed is faster, and the settled metal mud can enter the mud discharge channel independently.

2. The sewage lifting pumps that can be used for comprehensive wastewater reaction pool treatment include dosing pumps and magnetic pumps. The automatic dosing system needs to be equipped with a PH controller.

Process introduction: After the metal sludge settlement is completely completed, the wastewater is basically in a clarified state. The wastewater is released into the next treatment tank - the integrated wastewater reaction tank. The main elements such as chromium, copper, and nickel in the wastewater are precipitated, mainly through chemical addition.