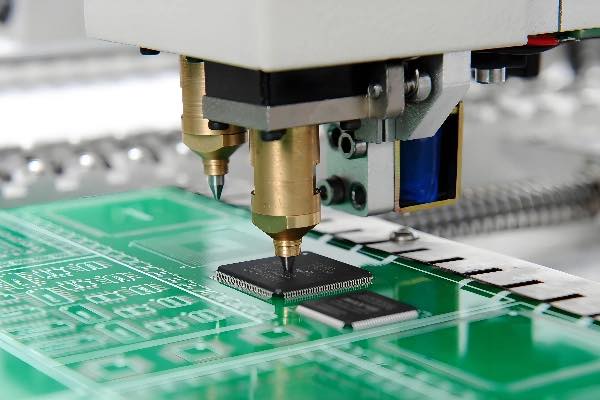

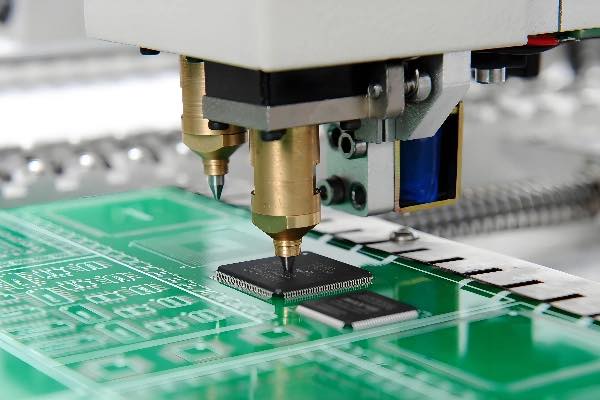

The application of PLASTIC DRIVE PUMP in the PCB (printed circuit board) industry is mainly reflected in the following aspects:

●

Chemical delivery:

A variety of chemicals are required in the PCB production process, such as etching liquid, cleaning agent and plating liquid. Its corrosion resistance makes it suitable for transporting these chemicals to avoid damage and contamination of materials.

● Leakage-free operation:

The design of the magnetic pump makes it almost leak-free during operation, reducing the risk of liquid pollution to the environment and ensuring production safety.

● High temperature and high acid and alkali liquid treatment:

Due to the heat and corrosion resistance of plastic materials, plastic magnetic pumps can handle high temperature, high acid and alkali liquids to meet various process requirements in PCB production.

● Cooling system:

During the PCB manufacturing process, some workstations will generate a lot of heat. Plastic magnetic pumps can be used for the circulation of coolant to help maintain the appropriate temperature of equipment and materials.

●

Waste liquid treatment:

Plastic magnetic pumps can effectively transport these waste liquids to the treatment system, helping to achieve environmental protection and resource recovery.

● Automation Integration: Modern PCB production is increasingly dependent on automation. Plastic magnetic pumps can be integrated with automatic control systems to achieve precise control of liquid delivery and improve production efficiency.

Contact us today to learn more about how plastic magnetic pumps can elevate your PCB manufacturing process!

-THE END-