How To Choose The Right Type Of Sewage Pump?

TIME:2024-06-11 Author:admin Views:

1. The model and performance of the pump need to meet the requirements of device flow, head, pressure, temperature, vapor flow, suction range and other process parameters.

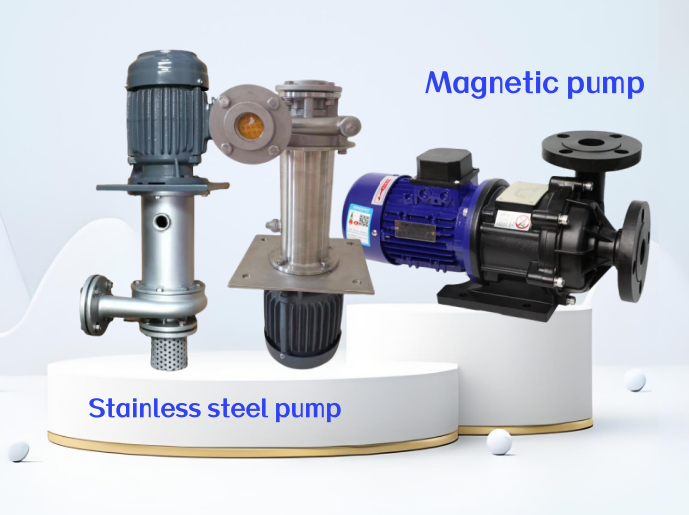

2. It must meets the requirements of the media characteristics: the pump conveying flammable, explosive toxic or precious media, requires a reliable shaft seal or leak-free pumps, such as magnetic drive pumps, diaphragm pumps, shielded pumps. For pumps conveying corrosive media, the requirement of convective components using corrosion-resistant materials, such as stainless steel corrosion-resistant pumps, engineering plastic magnetic drive pumps. For pumps conveying media containing solid particles, convective parts are required to use wear-resistant materials, and the shaft seal is flushed with clean liquid if necessary.

3. In the mechanical aspects of the need for high reliability, low noise, low vibration.

4. In the economy aspect should be comprehensively considered to the lowest total cost of equipment costs, operating costs, maintenance costs and management fees.

5. Centrifugal pump has characteristic of high speed, small size, light weight, high efficiency, high flow, simple structure, infusion of pulsation-free, smooth performance, easy to operate and maintain convenient and so on. Therefore, in addition to the following cases, centrifugal pumps should be selected as far as possible:

A. When there are measurement requirements, choose metering pumps.

B. When the head needs high requirement , the flow rate is very small and no suitable small flow high head centrifugal pumps can be selected, you can choose the reciprocating pump, such as cavitation requirements are not high when you can also choose the vortex pumps.

C. If the head is very low, the flow is very large, can choose axial flow pumps and mixed flow pumps

D. The medium viscosity is large (greater than 650 ~ 1000mm²/ s), can be considered to choose rotor pumps or reciprocating pumps (gear pumps, screw pumps)

E. When the media containing 75% of the gas, the flow rate is small and viscosity less than 37.4mm²/ s, you can choose the vortex pump.

F. Frequent start-up or irrigation pumps inconvenient occasions, should be used with self-priming performance pumps, such as self-priming centrifugal pumps, self-priming vortex pumps, pneumatic (electric) diaphragm pumps.

The basis for sewage pump selection:

Sewage pump selection based on the basis of pump selection, should be based on the process, water supply and drainage requirements, from five aspects to be considered, both the amount of liquid transport, device head, the nature of the liquid, piping arrangement and operating conditions.

1. Flow

Flow is one of the important performance data of the selected pump, which is directly related to the entire device's production capacity and conveying capacity. Such as the design institute process design can calculate the pump normal, minimum, maximum three kinds of flow. Selection of pumps, based on the maximum flow, taking into account the normal flow, in the absence of a maximum flow, usually 1.1 times the normal flow as the maximum flow.

2.Head

The head required by the device system is another important performance data to select the pump, generally used to amplify the 5% -10% margin after the head to select the type.

3.Liquid properties

Liquid properties, including the name of the liquid medium, physical properties, chemical properties and other properties, physical properties of temperature, density, viscosity, diameter of solid particles in the medium and the content of gas, etc., which relates to the system's head, the effective margin of cavitation calculations and the type of suitable pumps: chemical properties, mainly refers to the chemical corrosiveness and toxicity of the liquid medium is the selection of the pump material and selection of that type of shaft seal is an important basis.

4.Piping conditions

Device system piping arrangement conditions refers to the delivery height of the liquid delivery distance to the direction of the liquid delivery, suction such as the side of the lowest liquid level, the highest liquid level on the side of the discharge and some other data and pipeline specifications and their lengths, materials, fittings, specifications, quantity, etc., in order to carry out the Department of the comb head calculations and the calibration of the cavitation margin.

5. Operating conditions

There are many elements of operating conditions, such as liquid operation saturated vapor force , suction side pressure , discharge side container pressure , altitude, ambient temperature operation is intermittent or continuous, the pump position is fixed or removable.