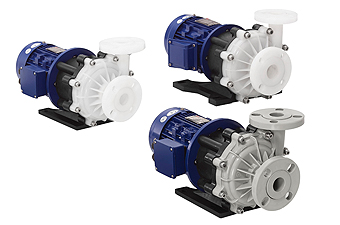

Why Does The Corrosion-resistant Magnetic Pump Leak?

TIME:2024-06-24 Author:admin Views:

On the basis of preliminary observation of leakage and judgment of leakage location, manual blocking observation was carried out. If there is no significant change in the amount of leakage, it is static. Dynamic seal problem: If the leakage of the seal has significant changes, it can be judged as a problem of friction between the dynamic and static rings. If the seal is sprayed along the axial direction of the leaking medium, most of the dynamic ring seal problems. If the leaking medium is sprayed from the surrounding or leaked from the water-cooling holes, most of the static ring seal failures. In addition, there may be other leakage channels.

Leakage occurring during trial operation corrosion resistance magnetic pump state test mechanical seal after the corrosion resistance magnetic pump operation process of high-speed rotation generated by the centrifugal force will inhibit the media leakage. Therefore, in the trial operation process, the mechanical seal leakage is basically due to the inter-axis and end cap seal failure exclusion, the static ring friction the damage caused.

The main reasons for the failure of the friction vice seal are:

1. Corrosion-resistant pump in the operation process, due to exhaust, cavitation, pressure and other anomalies, the axial force is large, making the static and dynamic ring contact surface separation.

2. When the mechanical seal is installed and used, the compression is too large, resulting in serious wear on the end face of the friction vice.

3. The movable ring seal is too tight, the spring can not adjust the movable ring axial floating;. Static ring seal ring is too loose, when the movable ring axial floating, static ring and static ring seat separation.

4. The working medium includes particulate matter, friction vice, probing device, electrostatic sealing end face and so on.

5. When this happens, most seals need to be removed and replaced.