The Usage Of The Kdnny Chemical Pumps

TIME:2024-06-03 Author:admin Views:

According to the mechanism of corrosion, it can be mainly divided into electrochemical corrosion and chemical corrosion.

1. Electrochemical corrosion mainly refers to the corrosion phenomenon caused by surface electrode reactions of metal materials in contact with electrolyte solutions. This reaction is generally an oxidation-reduction reaction, and the main factors are environmental humidity and temperature issues.

2. Chemical corrosion refers to the strong chemical reaction that occurs between the metal surface and the surrounding medium, causing certain damage to the metal. The main reasons for this corrosion are high temperature and dry environment. According to the appearance and causes of corrosion, it can be classified into delamination corrosion, industrial atmospheric corrosion, high-temperature oxidation corrosion, and marine atmospheric corrosion, etc.

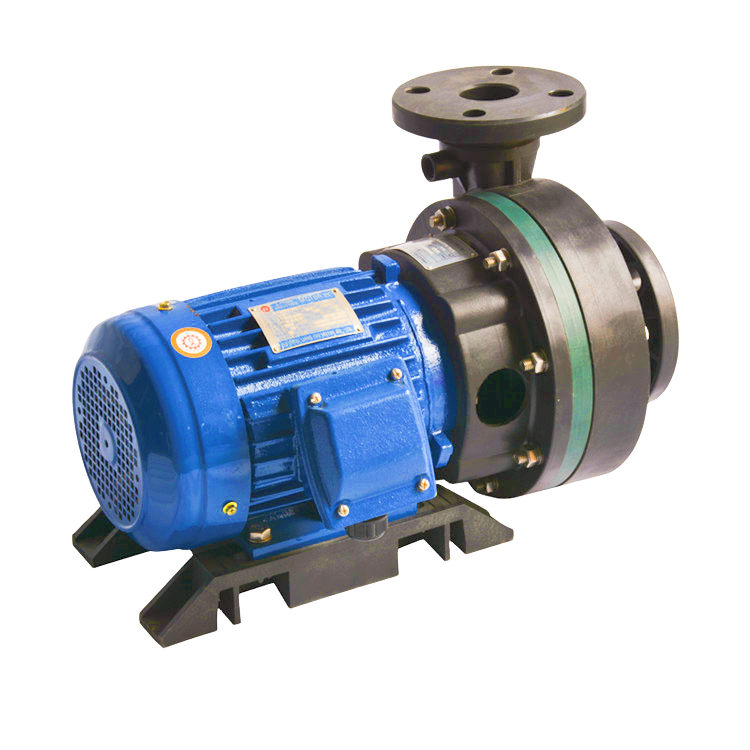

3. The corrosion-resistant chemical pump impeller is directly installed on the extended shaft of the motor, with a short axial size and compact structure. The pump and motor bearings are configured reasonably, which can effectively balance the radial and axial loads generated by the pump operation, thereby ensuring stable operation, low vibration, and low noise of the pump.

Classification based on working principle and structure:

1. Vane pump

When rotating through the pump shaft, various impeller blades are driven to apply centrifugal or axial force to the liquid, conveying it to pipelines or containers, such as centrifugal pumps, vortex pumps, mixed flow pumps, and axial flow pumps.

2. Positive displacement pump

A pump that uses continuous changes in the volume of the pump cylinder to transport liquids, such as reciprocating pumps, piston pumps, gear pumps, and screw pumps.

3. Other forms of pumps

There are electromagnetic pumps that use electromagnetic transmission to transport liquid conductive states. Pumps that use fluid energy to transport liquids, such as jet pumps, air elevators, etc.

Classification by chemical use:

1. Process pump

Including feed pump, reflux pump, circulation pump, flushing pump, sewage pump, make-up pump, output pump, etc.

2. Public engineering pumps

Including boiler pumps, cooling tower pumps, fire pumps, deep well pumps for water sources, etc.

3. Auxiliary pumps

Including lubricating oil pump, sealing oil pump, hydraulic transmission pump, etc.

4. Pipeline delivery pumps

Pumps for oil pipelines, pumps for loading and unloading vehicles, etc.

5. Acids, alkalis, and other liquid materials that are corrosive to metal materials are often encountered in petrochemical production.

The centrifugal pumps used to transport this type of material are collectively referred to as corrosion-resistant centrifugal pumps. The models of these pumps are all represented by F. Their working principle is similar to that of centrifugal clean water pumps, and their corrosion resistance is mainly determined by the properties of the materials used to manufacture these pumps.

The reason why most corrosion-resistant pumps can resist corrosion mainly depends on the material of the flow passage components of the pump.

For corrosion-resistant pumps, the material of the flow passage components of the pump needs to be selected according to the different conveying media. Plastic has a wide range of applications, with various materials such as polytetrafluoroethylene and polytetrafluoroethylene being reasonably formulated, molded, and processed.

Plastic corrosion-resistant pumps have strong corrosion resistance and advantages such as high mechanical strength, no aging, and no decomposition. They are ideal equipment for transporting various strong and weak acids, among which polytetrafluoroethylene is one of the corrosion-resistant materials, which can basically resist corrosion in any acid or alkali medium, and are known as the king of plastics.

Ceramics, enamel, glass, and other materials are also used in certain specific occasions to manufacture flow components for corrosion-resistant pumps.

During the test run, it is necessary to be fully prepared, strictly follow the operating procedures, and have the operators carry out the test run. Once any faults occur during the test run, they should be immediately eliminated.

Driven by the huge demand for oil today, the central and eastern regions and coastal areas of China have become regional markets with rapid development in the pump and valve industry. The traditional segmented smelting process has been challenged by "integrated" costs, the conventional cold rolling process has encountered quality competition, and the traditional price difference marketing model has experienced service competition.

As China's investment in environmental water treatment, coal chemical industry, and urban infrastructure further increases, the pump and valve industry will also benefit again. According to industry analysis, in the coming years, the demand for pump valves in the domestic market will continue to grow by over 10% and show an increasing trend year by year.