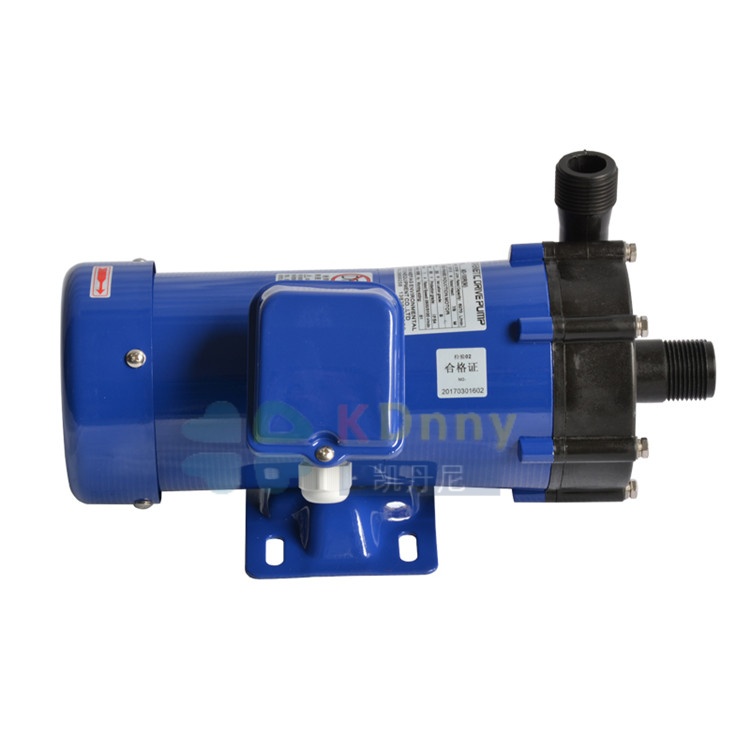

Magnetic Pump - MX series

TIME:2024-01-23 Author:admin Views:

TYPICAL APPLICATIONS

● Chemical Blending

● Water Treatment

● Plating

● Sodium Hypochlorite Generators

● Bio-Fuels

● Desalination

● Fume Scrubbers

PRODUCT FEATURES

● Self-radiating structure

Through heat-dispersion holes provided in the fixed portions of the impeller and the magnet capsule, the liquid around the spindle and the bearing is forced to circulate so that heat generated by sliding can be reduced effectively. Thus, thermal deformation and melt are prevented.

● Non-contact structure

By installing the driving magnet and the driven magnet in an inventive way, the movement of the magnet capsule is controlled by magnetic force to prevent the rear thrust and the rear portion of the bearing coming into contact with each other continuously even during dry running. This structure reduces heat generation and secures lubricant routes. (Except MX-70, 100)

● Volute casing divided into two sections

The MX series is the first resin magnet pump which uses the pump casing divided into the front casing and the rear casing to form a vortex chamber as an ideal form. Therefore, the internal leak phenomenon, which means that the liquid getting out of the impeller returns to the pump casing and is suppressed to a minimum and the liquid is efficiently guided to the discharge port to enhance overall efficiency.

● Robust structure

All stress bearing portions, such as the front and rear casings, are reinforced by means of ribs to improve the pressure resistance and the mechanical strength of the pump. The bearing is not only fixed by conventional press fit but is also sandwiched between the abutting portion in the depth of the magnet capsule and the rear end of the impeller to improve its reliability under high temperature. (Except MX-70, 100)

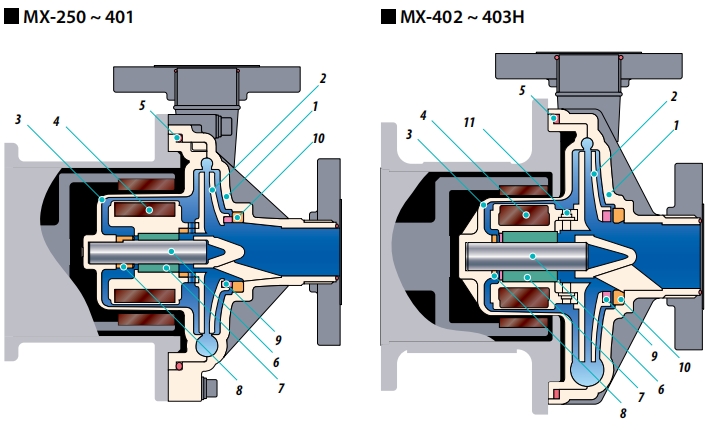

CONSTRUCTION

PARTS LIST

| No. | Description | Material | Model | Matterial code |

| 1 | Before the shell | GFRPP | MX-250~403H | CV(CE)/RV(RE) |

| 2 | Impeller | GFRPP | ||

| 3 | After the shell | GFRPP | ||

| 4 | Magnetic capsule | pp | ||

| 5 | O-ring | FKM(EPDM) | ||

| 6 | Pump shaft | High purity aluminum ceramics | ||

| 7 | Bearing | Carbon/PTFE/Aluminum Ceramic | ||

| 8 | After the thrust ring | CFRPPS(MX-402~403H) | MX-250~401 | AV(AE) |

| 9 | The interface ring | PTFE | ||

| 10 | Before the thrust ring | Aluminum Ceramic | ||

| 11 | Locking pin | GFRPPS(only in the 402~403H) |

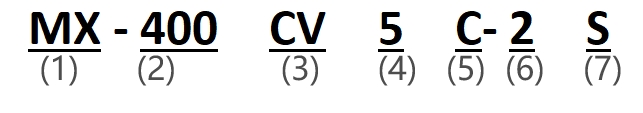

(1)Model: MX-pump material GFRPP

(2)In-outlet : 250 - 25×25 0.4kW 251 - 25×25 0.75kW 400 - 40×40 0.4kW

401 - 40×40 0.75kW 402 - 50×40 1.5kW 402H - 50×40 1.5kW

403 - 50×40 2.2kW 403H - 50×40 2.2kW

(3)Bearing: CV,CE - Carbon RV,RE - PTFE AV,AE - High purity aluminum ceramics

Pump Shaft:CV,CE - High purity aluminum ceramics RV,RE - High purity aluminum ceramics AV,AE - Aluminum Ceramic

O-ring: CV,CE - FKM(EPDM) RV,RE -FKM(EPDM) AV,AE - FKM(EPDM)

(4)Impeller code: 5 - 50Hz 6 - 60Hz 7 - impeller size change

(5)Motor type: unmark - TEFC indoor type C - TEFC outdoor type A - increase protection type (except for 2.2kW) E- New effeciency motor

(6)Motor specifiction: 2 - 3 phase 200/220V 3 - 3 phase 220/380V (Only for 250,251,400,401)

4 - 3 phase 380~440V (Only for 250,251,400,401) 6 - 3 phase 380V (only for 402,402H, 403, 403H)

7 - 3 phase 400/400/440V(only for 402,402H, 403, 403H) 8 - 3 phase 415V(only for 402,402H, 403, 403H)

9 - 3 phase 460V

(7)Special code: unmark - standard S - Special specifiction

These are MX Series of chemical pumps,the model number are as below:

MX-70M , MX-100M , MX-250 , MX-251 , MX-400 , MX-401 , MX-402 , MX-402H , MX-403 , MX-403H, MX-505

SPECIFICATION

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

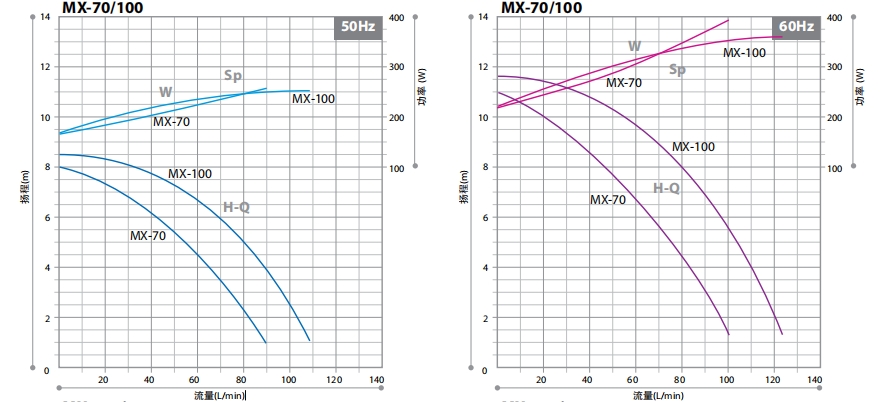

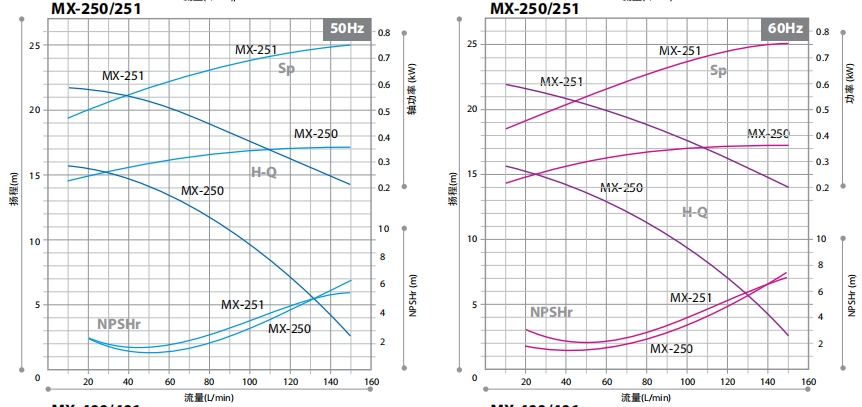

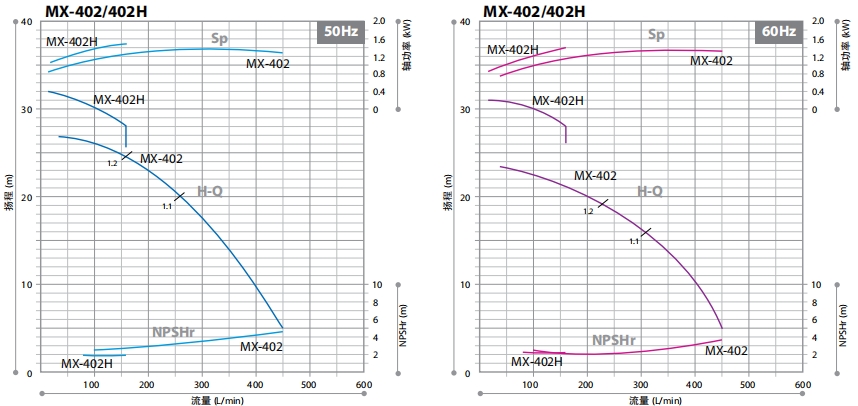

PERFORMANCE CURVE

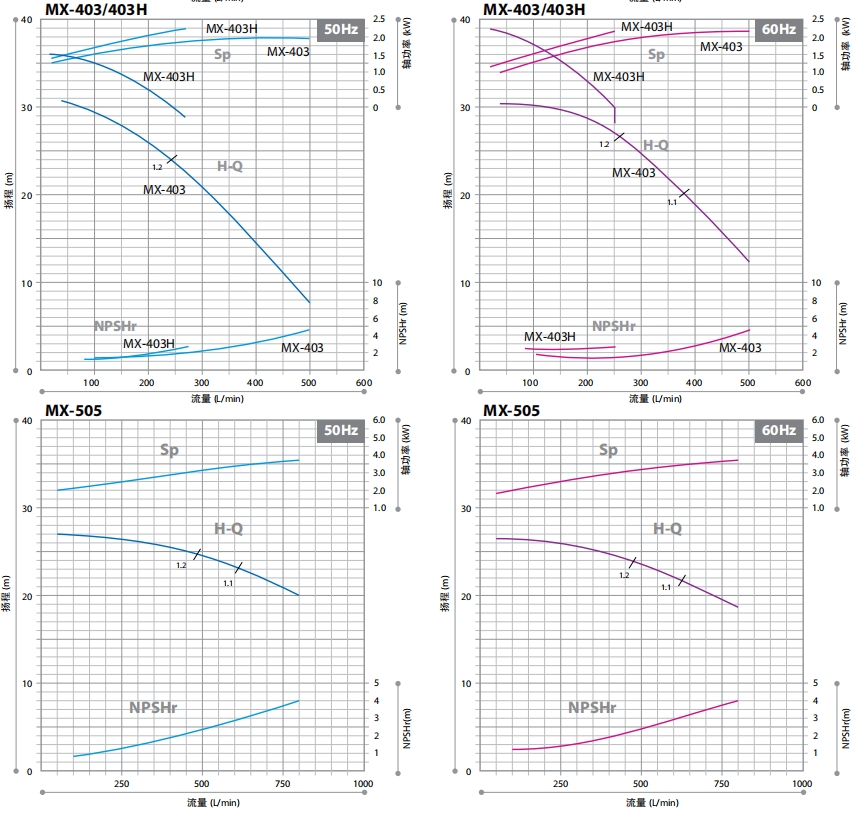

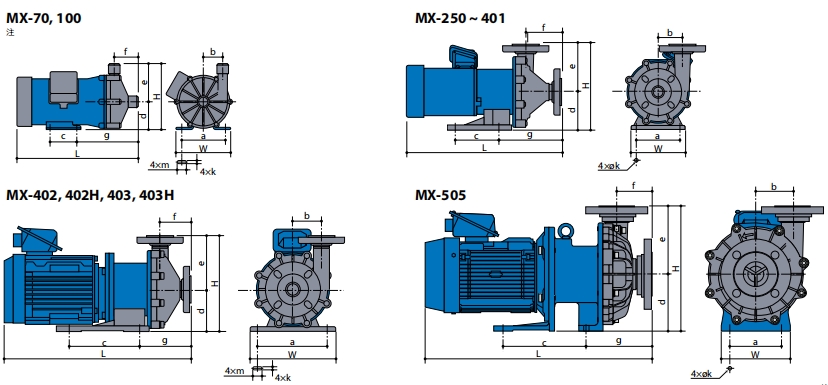

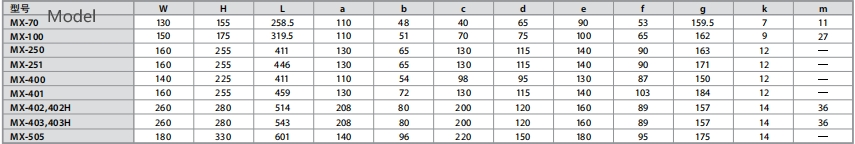

DIMENSION

UMIT:MM

While placing your order...

Please kindly provide us the following information.

1. Chemical: Name/Concentration/Temperature/Specific gravity/Viscosity.

2. Capacity needed:__________L/min

3. Head needed:__________M

4. Power: Voltage/Frequency