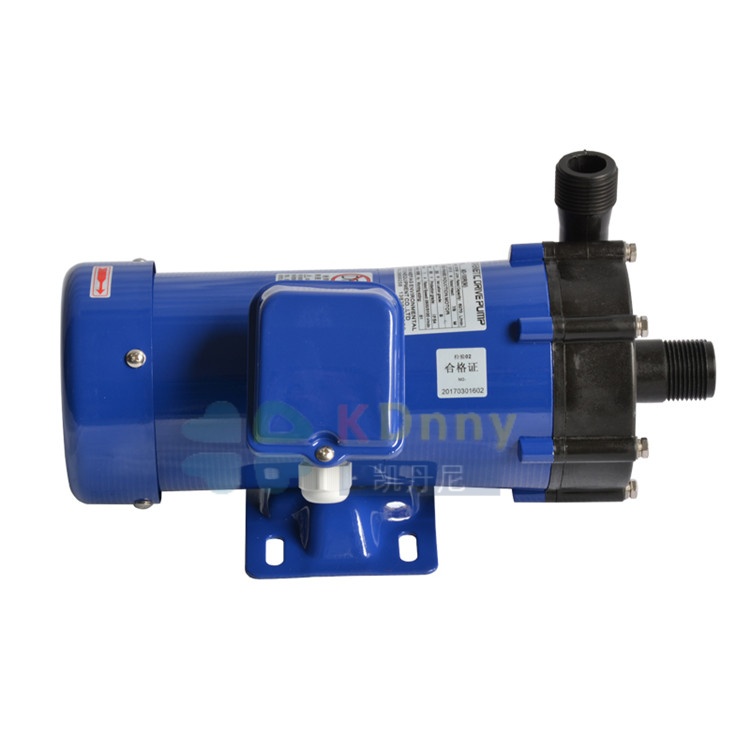

Magnetic pump - MDH Series

TIME:2024-01-23 Author:admin Views:

PRODUCT FEATURES:

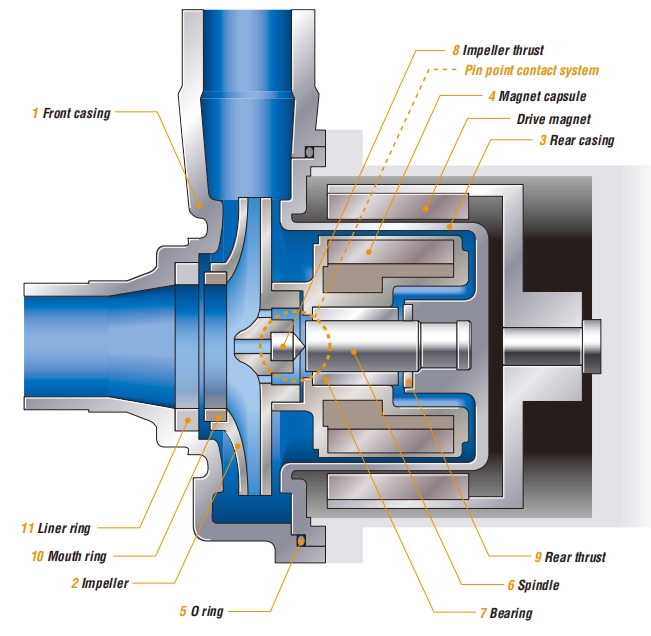

● Dry running is possible with a pin point contact system

● Excellent corrosion resistance

● Excellent durability

● Simple structure

● Pin-point contact system

CONSTRUCTION

PARTS LIST

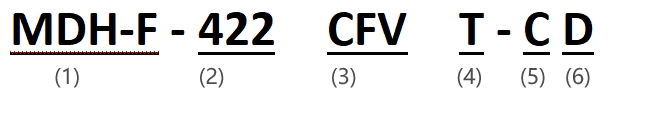

(1) Series: MDH - Casing material - GFRPP

MDH -F:Casing material - CFRETFE

(2) Suction×Discharge/Motor output:

400 - 40(G1 1/2) X 40(G1 1/2)/0.4kW

401 - 40(G1 1/2) X 40(G1 1/2) /0.75kW

422 - 50(G2)X40(G1 1/2)/1.5kW

423 - 50(G2)X 40(G1 1/2)/2.2kW

425 - 50(G2)X40(G1 1/2)/3.7kW

(3) Material of parts

MDH(Bearing/Spindle/O ring)

CV: Carbon/Alumina ceramic/FKM

RV: PTFE/Alumina ceramic/FKM

FE: Carbon/High purity alumina ceramic/EPDM

MDH -F(Bearing/Spindle/O ring)

CFV: High-density carbon/High-purity alumina ceramic/FKM

AAV: Alumina ceramic /Alumina ceramic/FKM(For 400 and 401 types)

:High-purity alumina ceramic /High-purity alumina ceramic/FKM(For 422 and 423 types)

(4) Impeller symbol

MDH: 5 -50Hz 6 - 60Hz

MDH -F: T,V,W - For 50Hz X,Y,Z - For 60Hz

(5) Type of motor: No symbol - TEFC, indoor type

C - TEFC,outdoor type

A -Increased safety type(422 and 423 types do not have increased safety types)

(6) Pin point contact system: D - Dry running operation for one hour is permissible.

E -Dry run is not possible.

This is MDH of Chemical pumps,the model numbers are as below:

MDH-440 , MDH-441 , MDH-422 , MDH-423 , MDH-425 , MDH-F440 , MDH-F441 , MDH-F422 , MDH-F423

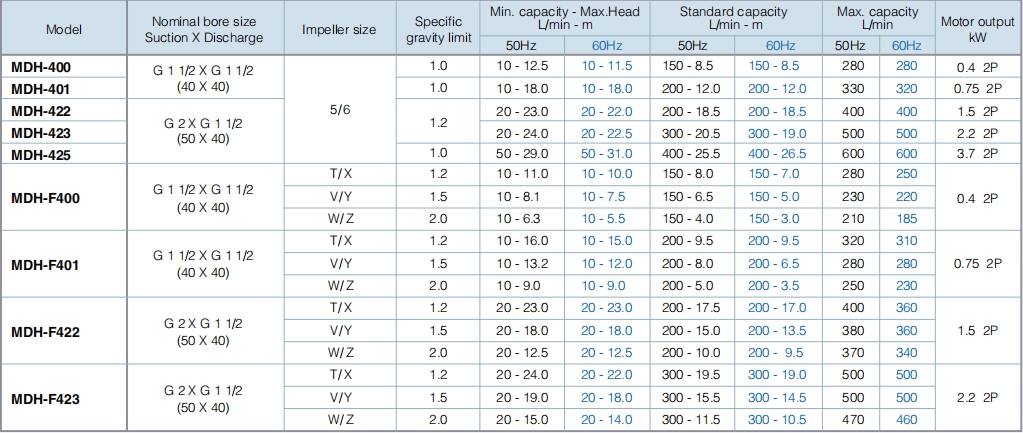

SPECIFICATION

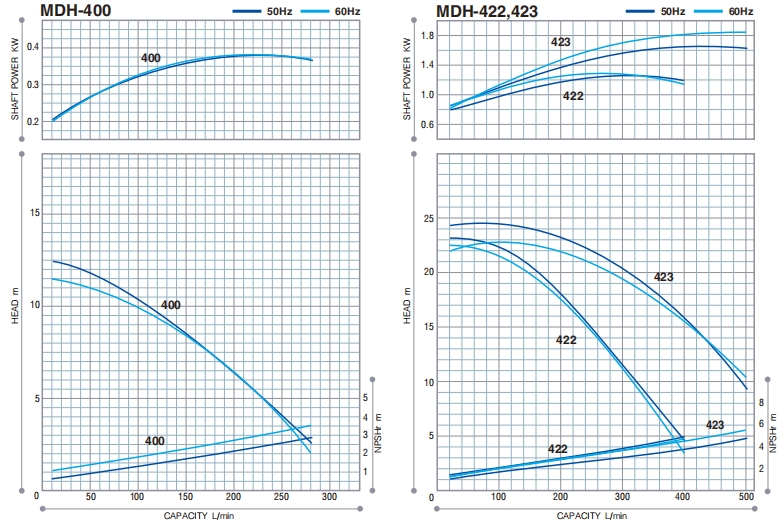

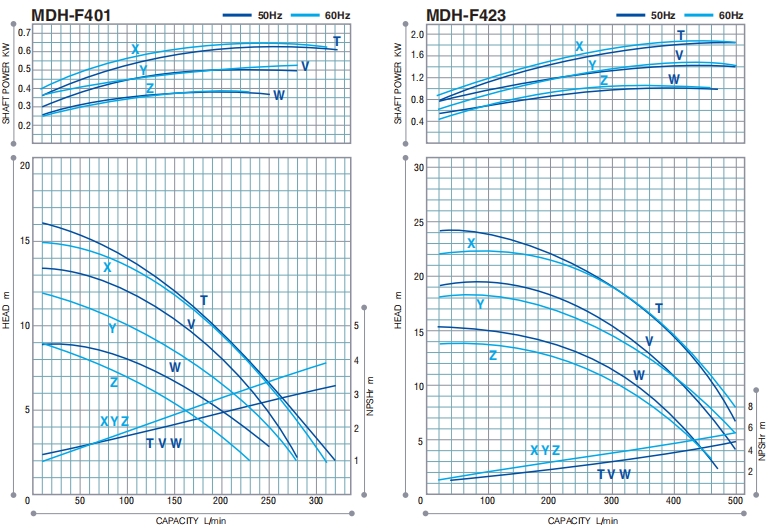

PERFORMANCE CURVES

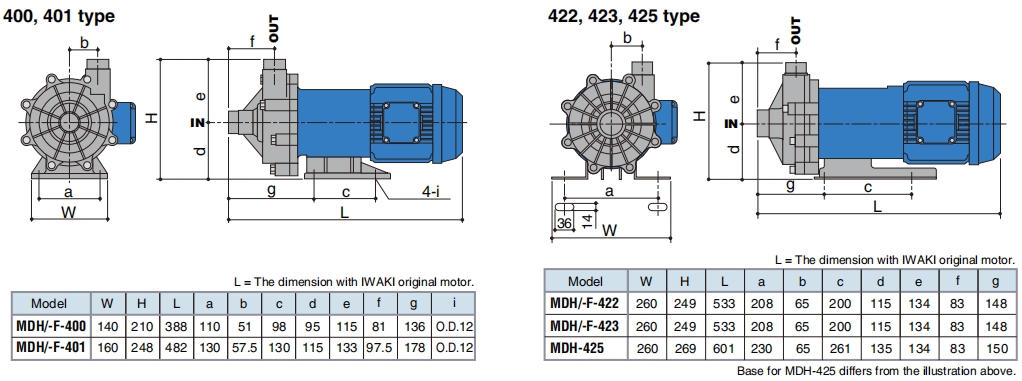

DIMENSION UMIT:MM

While placing your order...

Please kindly provide us the following information.

1. Chemical: Name/Concentration/Temperature/Specific gravity/Viscosity.

2. Capacity needed:__________L/min

3. Head needed:__________M

4. Power: Voltage/Frequency