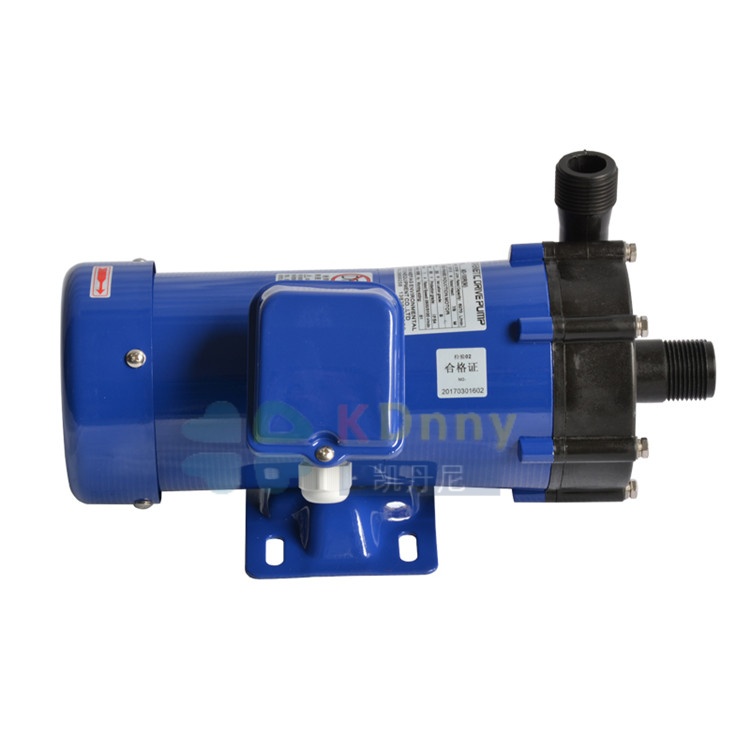

Magnetic pump - YD Series

TIME:2024-07-26 Author:admin Views:

TYPICAL APPLICATIONS

● For transferring liquid in PCB equipment

● For transferring liquid in water / air treatment

● For circulating plating liquid

● For transferring chemical liquid

PRODUCT FEATURES

● Low flow & high head ara available.

● Possible to select depending on the specific gravity of the liquid to use.

● Loose flnage is adopted for free installation

● Air lock prevention is built in.

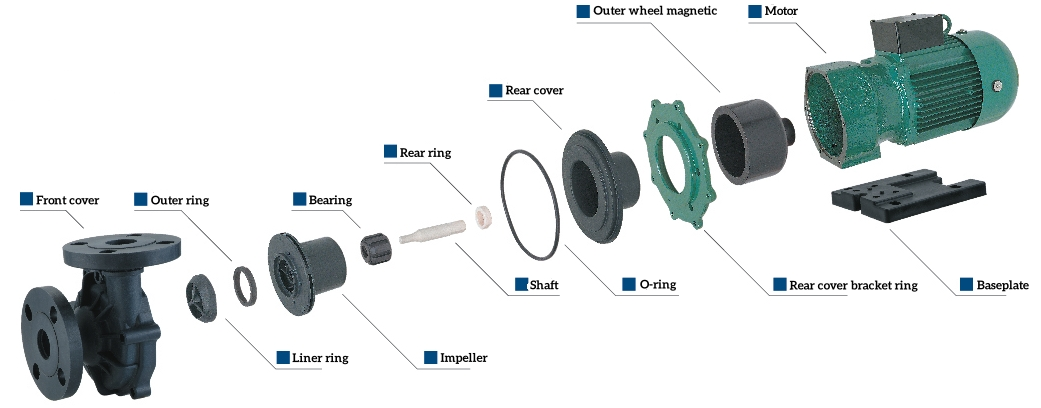

PARTS LIST

| Description | Material | |

| GS type | GSFtype | |

| Front Cover | GFR PP | CFR PP |

| Line ring | Ceramic+GFR PP | Ceramic+ETFE |

| Outer ring | CFR PTFE | |

| Impeller | (GFR)PP+magnetic | CFR ETFF+magnetic |

| Bearing | Carbon/Ceramic/TEFLON/ | |

| Shaft | Ceramic/ SIC | |

| Rear ring | Ceramic/ SIC | |

| O ring | EPDM/FPM | |

| Rear cover | GFR PP | CFR ETFE |

| Rear cover bracket ring | FC200 | |

| Outer wheel magnetic | FCD4500-10+magnetic | |

| Motor | FC200+Aluminium alloy motor | |

| Baseplate | GFR PP/FC200 | |

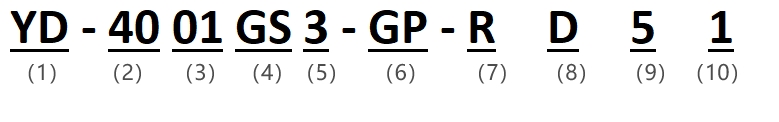

| No. | Description | Indentification | ||

| (1) | Series | YD | ||

| (2) | Doscharge Bore | 25 - 25A(1'') | 40 - 40A(1.5'') | 50 -50A(2'') |

| (3) | Motor Output | 00-0.4kW | 01 - 0.75kW | 02 - 1.5kW |

| 03 - 2.2kW | 06 - 3.7kW | |||

| (4) | Model | GS | GSF | |

| (5) | Type of Motor | 1 - IE1 | 2 - IE2=GB3 | 3 - IE3=GB2 |

| (6) | Pump Material | GP - GFR PP | CF - CFR ETFE | |

| (7) | Bearing Material | C - CARBON | R - CFR PTFE | A - Alumina CERAMIC |

| (8) | O-ring Material | E - EPDM | D - FPM | |

| (9) | Frequency | 5 - 50Hz | 6 - 60Hz | |

| (10) | Specific Gravity | 0 - 1.0 | 1 - 1.05/1.1 | 2 - 1.2 |

| 3 - 1.3 | 4 - 1.4 | 5 - 1.5 | ||

| 6 - 1.6 | 9 - 1.9 | |||

These are YD Series of chemical pumps,the model numbers are as below:

YD-2500GS1 , YD-2501GS3 , YD-2502GS3 , YD-2503GS3 , YD-4000GS1 , YD-4001GS3 , YD-4002GS3 , YD-4003GS3 , YD-4005GS3 ,

YD-2500GSF1 , YD-2501GSF3 , YD-2502GSF3 , YD-2503GSF3, YD-4000GSF1 , YD-4001GSF3 , YD-4002GSF3 , YD-4003GSF3 , YD-4005GSF3

SPECIFICATION

| Main material: GFR PP | |||||||

| Model | Bore(mm) |

Limited S.G. |

Std. performance (m_L/min.) |

Output (kW) |

Weight with Motor(Kg) |

||

| Suc. | Dis. | 50Hz | 60Hz | ||||

| YD-2500GS1 | 25 | 25 | 1.0 | 14 - 50 | 14 - 50 | 0.4 | 19.5 |

| 1.3 | 10 - 50 | 10.5 - 50 | |||||

| 1.5 | 9 - 50 | 9 - 50 | |||||

| YD-2501GS3 | 1.0 | 21 - 50 | 21.5 - 50 | 0.75 | 21.5 | ||

| 1.3 | 17 - 50 | 17 - 50 | |||||

| 1.5 | 15 - 50 | 15 - 50 | |||||

| YD-2502GS3 | 1.0 | - | 34 - 50 | 1.5 | 26.5 | ||

| 1.3 | 25.5 - 50 | 27 - 50 | |||||

| 1.5 | 24 - 50 | 25 - 50 | |||||

| YD-2503GS3 | 1.0 | - | 37 - 50 | 2.2 | 28.5 | ||

| 1.3 | - | 34 - 50 | |||||

| 1.5 | - | 31 - 50 | |||||

| YD-4000GS1 | 40 | 40 | 1.05 | 11 - 100 | 11 - 100 | 0.4 | 16.5 |

| 1.3 | 9 - 100 | 7.5 - 100 | |||||

| 1.5 | 7.5 - 100 | - | |||||

| YD-4001GS3 | 40 | 40 | 1.05 | 15 - 150 | 15 - 150 | 0.75 | 19.5 |

| 1.3 | 12 - 150 | 12 - 150 | |||||

| 1.5 | 10.5 -150 | 10 - 150 | |||||

| YD-4002GS3 | 50 | 40 | 1.1 | 19 - 200 | 19 - 200 | 1.5 | 25.5 |

| 1.3 | 17 - 200 | 16 - 200 | |||||

| 1.5 | 14.5 - 200 | 14.5 - 200 | |||||

| YD-4003GS3 | 50 | 40 | 1.1 | 23 - 200 | 25 - 200 | 2.2 | 27.5 |

| 1.3 | 21 - 200 | 24 - 200 | |||||

| 1.5 | 19.5 - 200 | 20.5 - 200 | |||||

| YD-4005GS3 | 50 | 40 | 1.1 | - | 34 - 200 | 3.7 | 41.5 |

| 1.3 | - | 31 - 200 | |||||

| 1.4 | 24 - 200 | - | |||||

| 1.5 | - | 28 - 200 | |||||

| YD-5005GS3 | 65 | 50 | 1.1 | 20 - 500 | 20 - 500 | 3.7 | 45 |

| 1.3 | 18 - 500 | 18 - 500 | |||||

| 1.5 | 15 - 500 | 15 - 500 | |||||

| YD-2500GSF1 | 25 | 25 | 1.2 | 9 - 50 | 9 - 50 | 0.4 | 20.5 |

| 1.5 | 7 - 50 | 6.5 - 50 | |||||

| 1.9 | 5.5 - 50 | - | |||||

| YD-2501GSF3 | 1.2 | 16.5 - 50 | 15 - 50 | 0.75 | 22.5 | ||

| 1.5 | 14 - 50 | - | |||||

| 1.6 | - | 11 - 50 | |||||

| 1.9 | 11.5 - 50 | - | |||||

| YD-2502GSF3 | 1.2 | 24 - 50 | 26 - 50 | 1.5 | 28 | ||

| 1.5 | 22 - 50 | 22 -50 | |||||

| 1.9 | 18 - 50 | 18 - 50 | |||||

| YD-2503GSF3 | 1.2 | - | 33 - 50 | 2.2 | 30 | ||

| 1.5 | - | 28 - 50 | |||||

| 1.9 | 23.5 - 50 | 25.5 - 50 | |||||

| YD-4000GSF1 | 40 | 40 | 1.2 | 8.5 - 100 | 9 - 100 | 0.4 | 17.5 |

| 1.5 | 7 - 100 | 6 - 100 | |||||

| 1.9 | 5.5 - 100 | - | |||||

| YD-4001GSF3 | 40 | 40 | 1.2 | 12 - 150 | 11.5 - 150 | 0.75 | 20.5 |

| 1.5 | 9 - 150 | 9 - 150 | |||||

| 1.9 | 8 - 100 | 9 - 100 | |||||

| YD-4002GSF3 | 50 | 40 | 1.2 | 18 - 200 | 17.5 - 200 | 1.5 | 27 |

| 1.5 | 15 - 200 | 14 - 200 | |||||

| 1.9 | 12.5 - 200 | 10.5 - 200 | |||||

| YD-4003GSF3 | 50 | 40 | 1.2 | 21 - 200 | 22.5 - 200 | 2.2 | 29 |

| 1.5 | 19 - 200 | 19.5 - 200 | |||||

| 1.9 | 15.5 - 200 | 15 - 200 | |||||

| YD-4005GSF3 | 50 | 40 | 1.2 | - | 30 - 200 | 3.7 | 43 |

| 1.3 | 25 - 200 | - | |||||

| 1.5 | - | 27.5 - 200 | |||||

| 1.9 | - | 23 - 200 | |||||

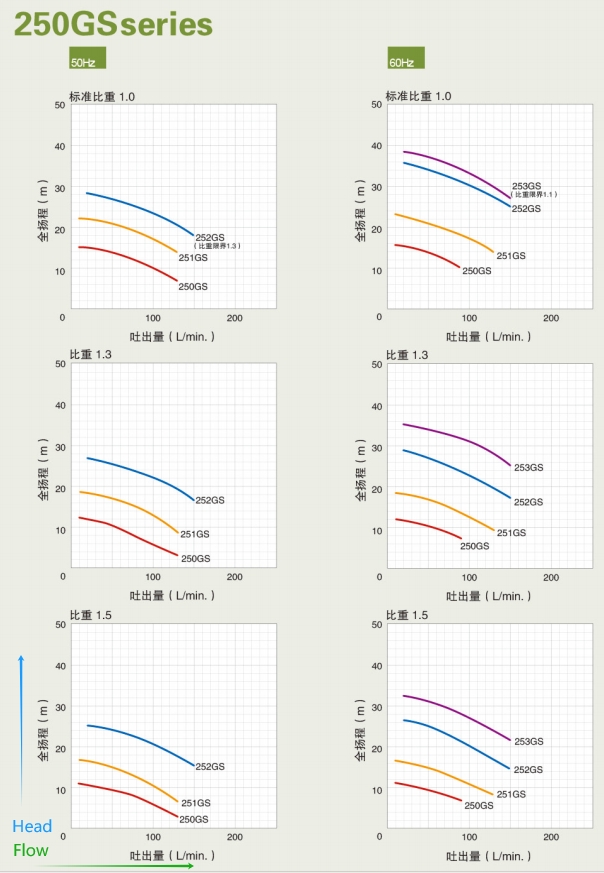

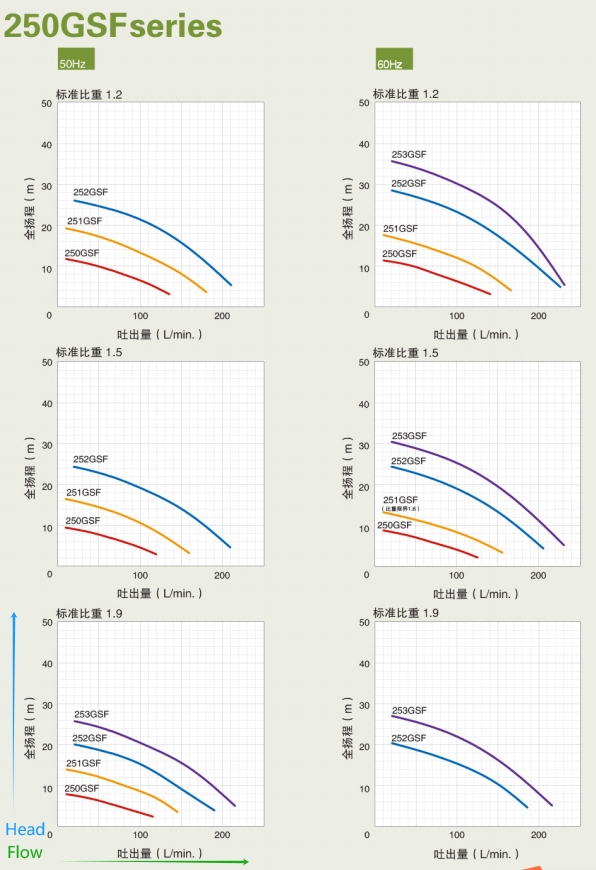

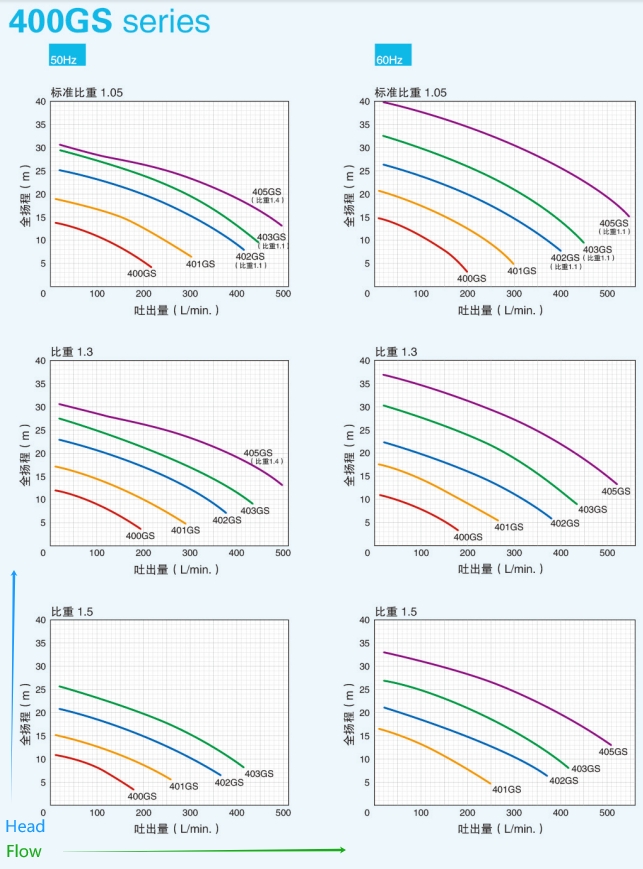

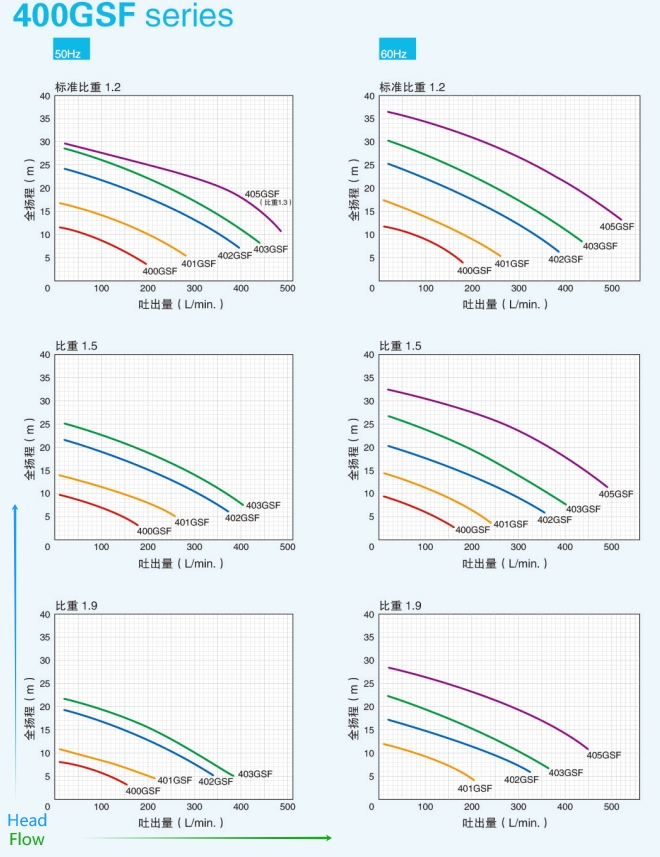

PERFORMANCE CURVE

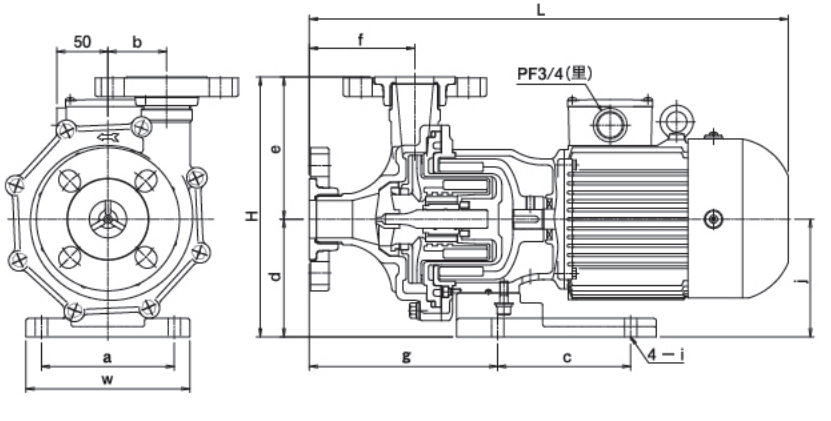

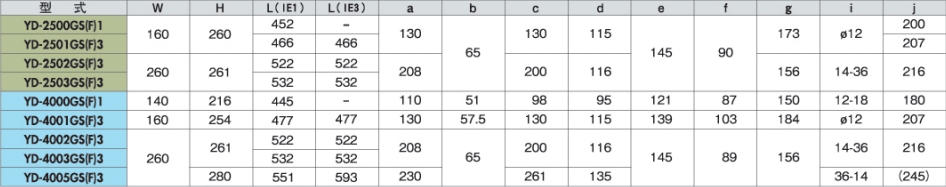

DIMENSION

UMIT:MM

While placing your order...

Please kindly provide us the following information.

1. Chemical: Name/Concentration/Temperature/Specific gravity/Viscosity.

2. Capacity needed:__________L/min

3. Head needed:__________M

4. Power: Voltage/Frequency