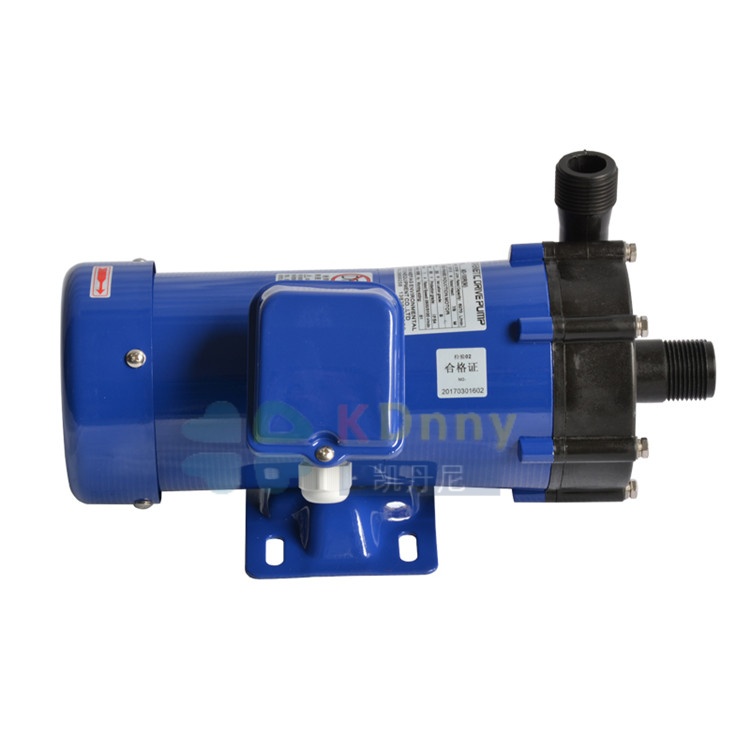

Magnetic pump- MP series

TIME:2024-11-12 Author:admin Views:

TYPICAL APPLICATIONS

● Chemical industry: Sodium carbonate industry (production of hydrochloric acid and hypochlorite); production of fluoride and chemical fertilizers

● Pharmaceutical industry:roduction of light-emitting chemicals (EL) for semiconductors, pesticides, pharmaceuticals, and water treatment chemicals.

● Metal Industry: Aluminum oxide film treatment equipment; wire drawing, degreasing and pickling in steel tying

● Photograph industry: instant photo system; X-ray film, black-and-white, color photo development and tanning.

● Electroplating industry: Circulation and filtration of various types of electroplating solutions.

● Mining industry: metal smelting (conveying and circulating electrolyte); washing treatment of waste liquid.

● Pollution Control: Adding sewage treatment chemicals to medicinal tanks; collecting and transporting waste liquids; exhaust gas absorption equipment (deodorizing devices).

PRODUCT FEATURES

● Outstanding Acid / Alkaline Resisting Capability

The material of pump body has four kinds to choose from, including PP(Polypropylene), GFRPP(Glass Fiber Filled Polypropylene), PVDF(Natural PVDF), CFRETFE(Carbon Fiber Filled ETFE). Correct choice of pump body material depends on acid / alkaline density of solution. To satisfied the market demand,The PP / GFRPP material can resist temperature up to 75℃. The PVDF material can resist temperature up to 90℃. The CFRETFE material can resist temperature up to100℃. In application almost all solutions can be transferred with safety.

● Corrosion Resisting

The major parts of the pump feature outstanding corrosion-resist capability. For example the pump spindle can be made from ceramic and SIC. The ceramic spindle is generally applied for low corrosion liquid. The SIC spindle is excellent for high corrosion liquid.

● Sealless and No Leakage

Eliminate the mechanical shaft seal design on the conventional pump, the high performance magnetic drive pump features complete seal. It fully eliminates the problem of environmental pollution due to pump damage.

● Easy to Assemble

The internal parts of a magnetic drive sealless pump are fully standard for easy assembling completely constructed with high performance. Parts replacement is easy to made without need to of any specially tool. It features convenient maintenance, dismantling and inspection for time saving service.

● Maximum Durability

The MP series pump motor is equipped with temperature protection device which avoids motor damaged due to high temperature caused by overload.

● Versatile Applications

The magnetic drive sealless pump MP series is ideal for low capacity with high head or high capacity with low head applications. It is widely applied in various industrial process. Such as PCB process, chemical industry, circulated filtering, etching, plating, surface treatment, polluted water treatment,etc. these pumps assure outstanding performance and maximum durability.

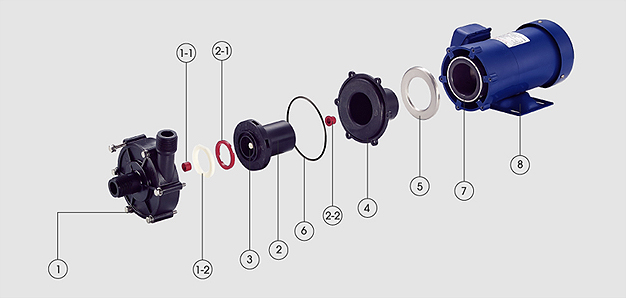

CONSTRUCTION

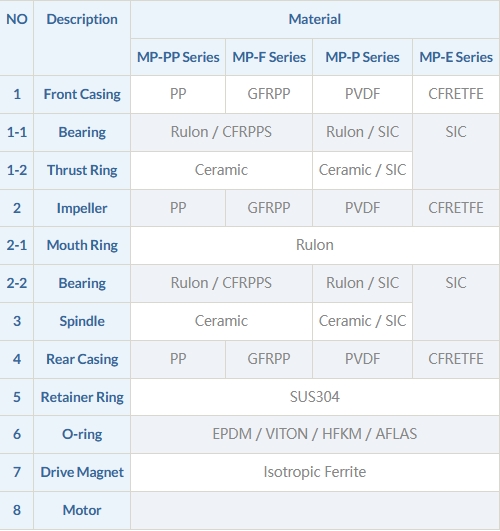

PARTS LIST

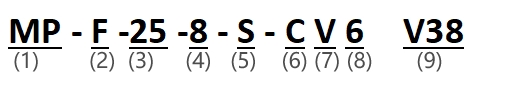

(1)Model:MP

(2)Pump Material:PP-PP F - CFRPP P - PVDF E-CFRETFE

(3)In-outlet: 20 - 3/4’’ 25 - 1’’

(4)Power: 3 - 45W 4 - 65W 5 - 90W

7 -180W 8 - 260W

(5)Collection: S - SCREW H - HOSE

(6)Spindle: C -Ceramic S - SIC

(7)Rubber: V - VITON E - EPDM P - PFA

(8)Frequency: 5 - 50Hz 6 - 60Hz

(9)Voltage: V11-110V/1∅ V22-220V/1∅

V38-220V/3∅ V41-208V/3∅

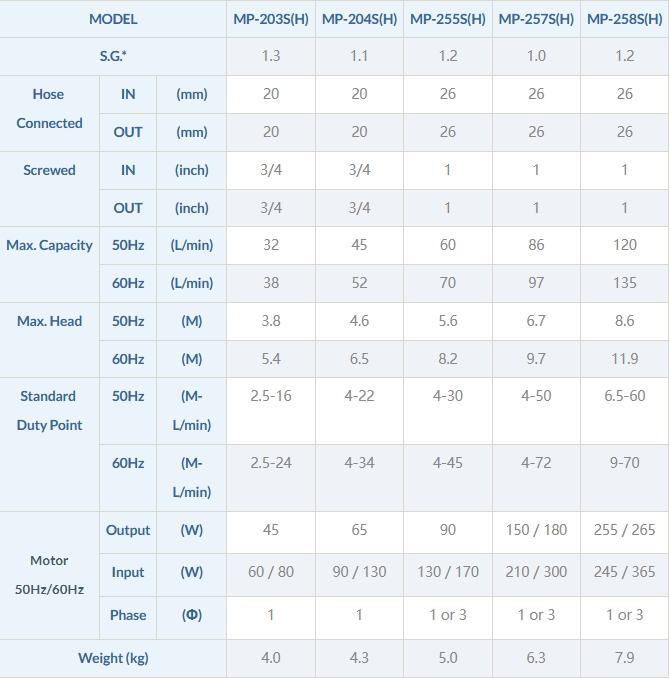

SPECIFICATION

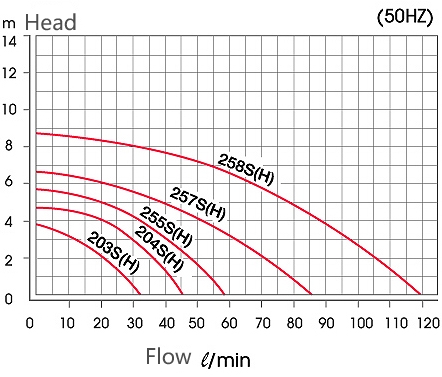

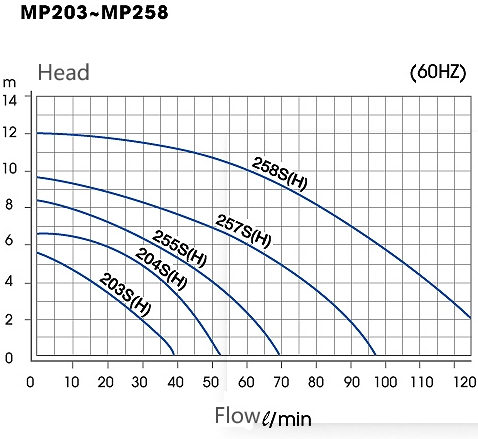

PERFORMANCE CURVES

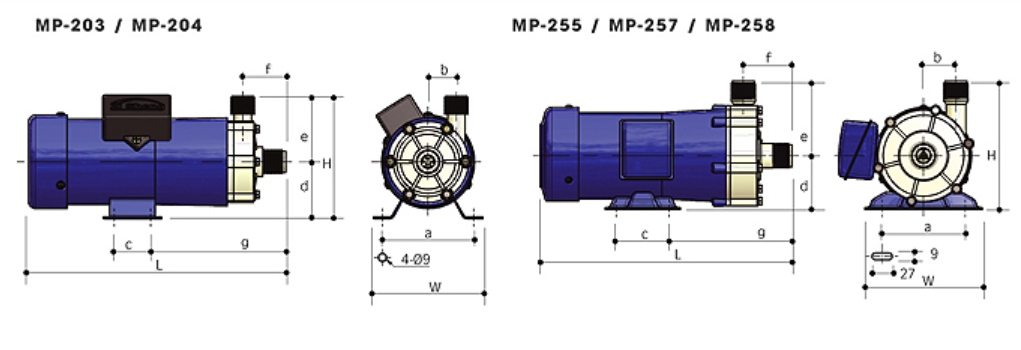

DIMENSION

UMIT:MM

While placing your order...

Please kindly provide us the following information.

1. Chemical: Name/Concentration/Temperature/Specific gravity/Viscosity.

2. Capacity needed:__________L/min

3. Head needed:__________M

4. Power: Voltage/Frequency