The KTD/KSTD series pumps are dependable pumps. The full motor horsepower is translated into pumping power via the shaft. These pumps are used in a wide range of applications from chemical recirculation to process modules. There are no seals or bushings that can be damaged if the pumps run dry. The vertical design has a maximum fluid temperature of 167F (75℃) to 185F(85℃), depending on the materials of construction, and can handle the most abrasive solutions. The KTD/KSTD series pumps are designed to run inside or outside the tank or process module. However,the installation instructions should be followed .They feature slotted air gap in the pump base and a double-dry seal, thereby preventing corrosive vapor from penetrating to the motor bearings. The pump shaft incorporates a keyed lock to the impeller so that if the pumps run in reverse, the housing and the impeller will not be damaged.

TYPICAL APPLICATIONS:

●Chemical or water recirculation

● Fume scrubbers/ waste treatment

●Various plating solutions recirculation

The difference between KTD and KSTD series is single vapor seal or double vapor seals.The double vapor seals performs much more better than single vapor seal in sealing the backflow and vapor.

PRODUCT FEATURES:

● 1 year warranty.

● CPVC,CFRPP,PVDF, FRPP construction.

● Non-metallic solution contact (outside of the tank).

● Max. fluid temperature:FRPP/CPVC/CFRPP167F(75℃) PVDF 185F(85C).

● High efficiency-low operating cost, leakfreeoperation and easy maintenance.

● Excellent chemical resistance.

● No seals or bearings in pump head to wear out.

● Continuous chemical duty TEFC motors with oversized bearings in motor casing.

● Vertical pumps can run-dry without damage to vapor seal.

● Single vapor seal of KTD series or double seals of KSTD series prevents corrosive vapors from entering the motor base.

● Thick reinforced ribbing in all molded parts.

● Simplicity of design makes these pumps easy to service and operate.

● Vented pump base.

● The pump can be mounted outside of tank or process module. For mounted inside the tank, the bolts should be changed depending on the solution.

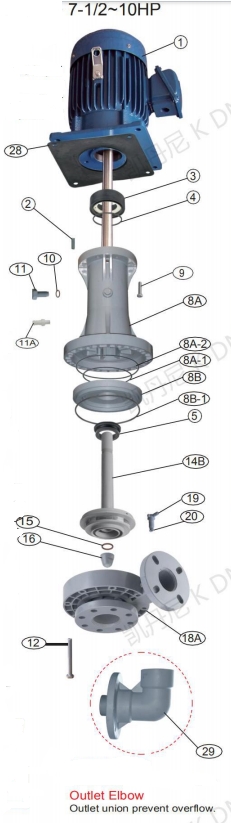

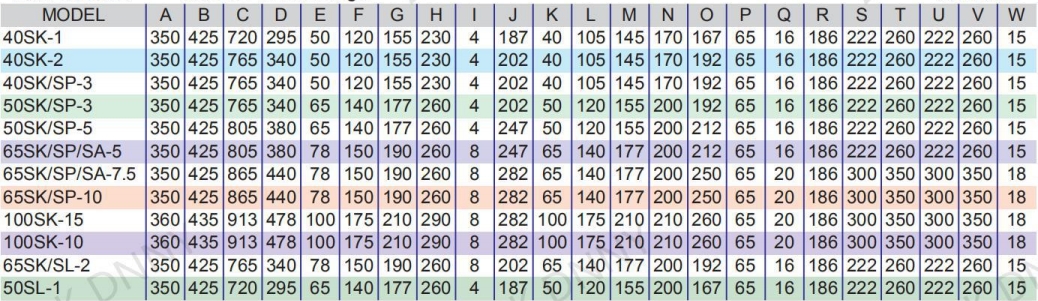

CONSTRUCTION

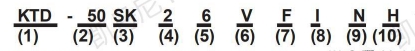

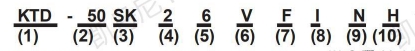

(1)TYPE: KTD - Single impeller single vapor seal KSTD - Single impeller double vapor seal

(1)TYPE: KTD - Single impeller single vapor seal KSTD - Single impeller double vapor seal

(2) Outlet code: 40 - 1-1/2'' 50-2''

65 - 2-1/2'' 80-3''

100 - 4''

(3)Specific gravity: SK-1.1 SP-1.4 SL- Low speed 4P

(4)Power: 1 - 1HP 2 - 2HP 3 - 3HP 5 - 5HP 7 - 7.5HP 10 - 10HP 15 - 15HP

(5)Frequency: 5 - 50HZ 6 - 60HZ

(6)O-ring : V - VITON N - NBR E - EPDM

(7)Pump material: F-FRPP, K-PVDF, C-CPVC, P-CFRPP

(8)I - In-slot mounting O- Out-slot mounting

(9)S-Special model N-Normal model

(10)H- add overflow exhaust hose

Currently, we have below model of TD series Vertical pump:

KTD-40SK-1 , KTD-40SK-2 , KTD-40SK-3 , KTD-50SK-3 , KTD-50SK-5 , KTD-65SK-5 , KTD-65SK-7.5 , KTD-65SK-10

KTD-80SA-5 , KTD-80SA-7.5 , KTD-80SA-10 , KTD-100SA-10 , KTD-100SA-15 , KTD-125SA-15 , KTD-125SA-20

KTD-40SP-3 , KTD-50SP-3 , KTD-50SP-5 , KTD-65SP-7.5 , KTD-65SP-10 , KTD-100SP-15 , KTD-50SL-1 , KTD-80SL-2 , KTD-100SL-3 , KTD-125SL-3

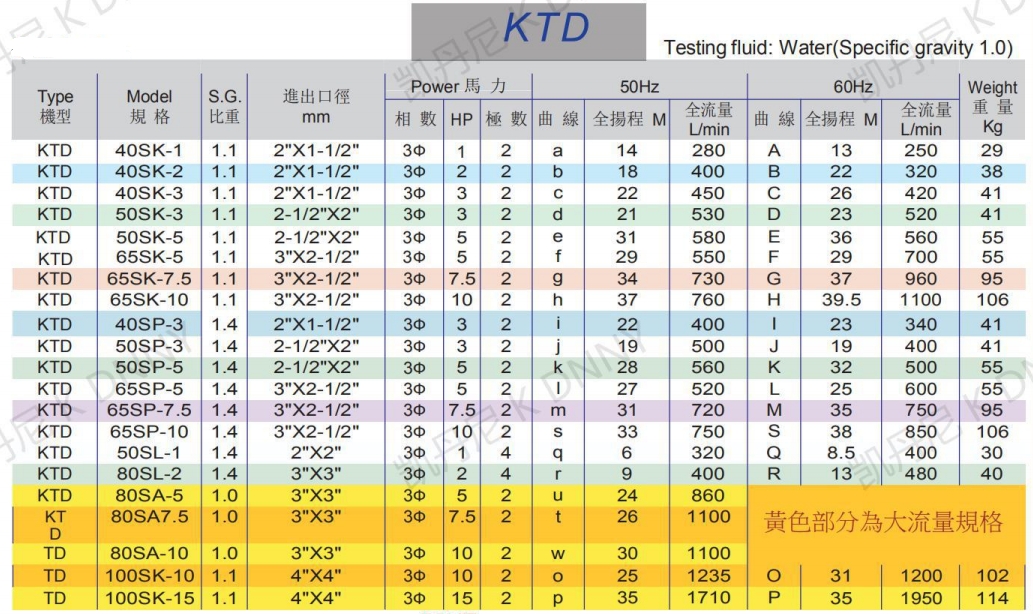

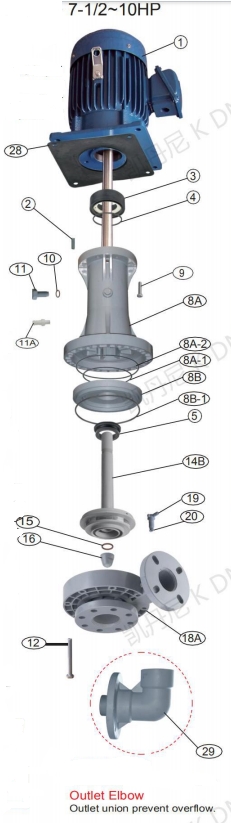

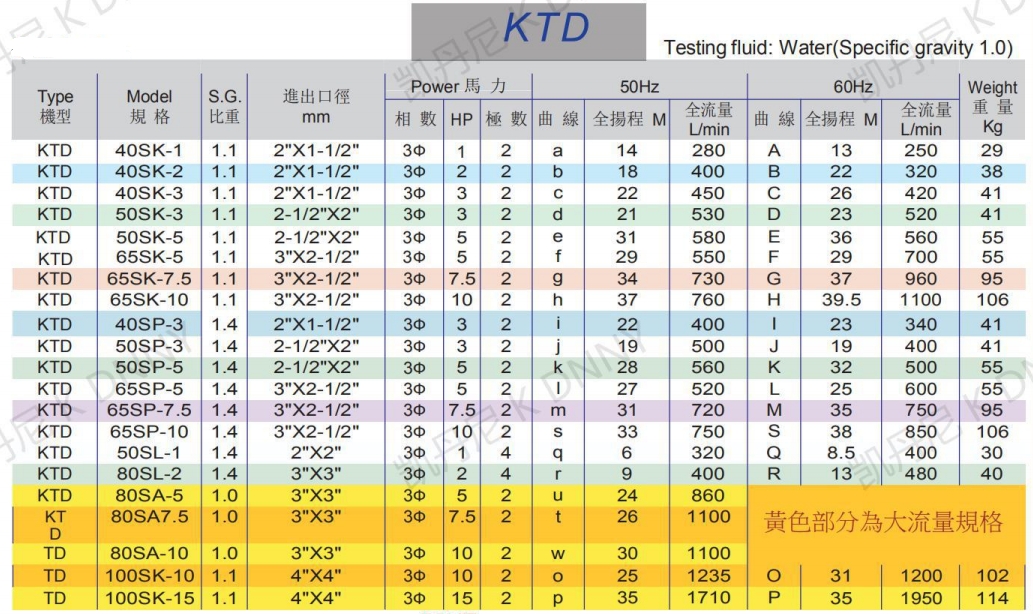

SPECIFICATION

SPECIFICATION

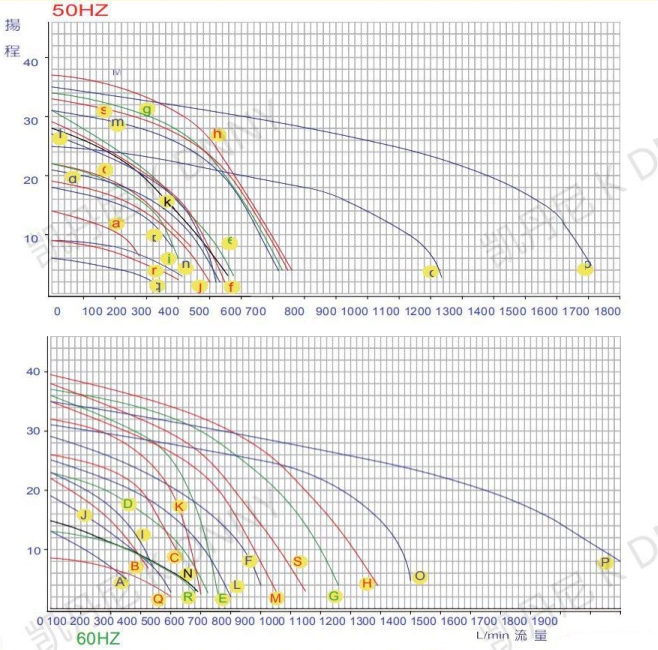

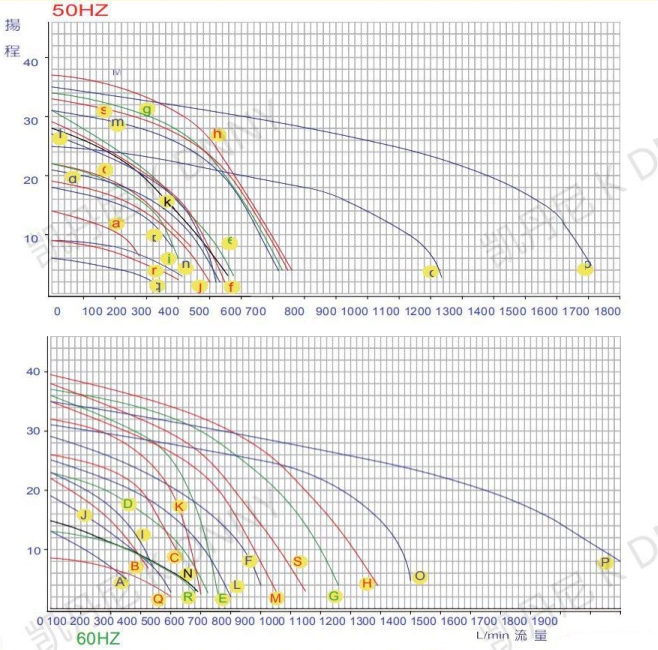

PERFORMANCE CURVE

PERFORMANCE CURVE

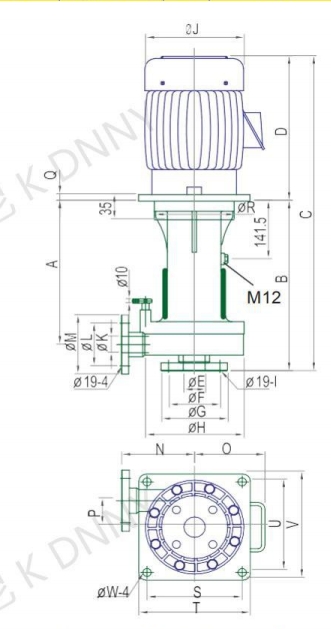

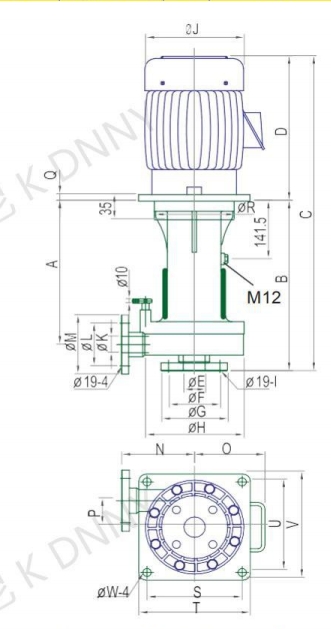

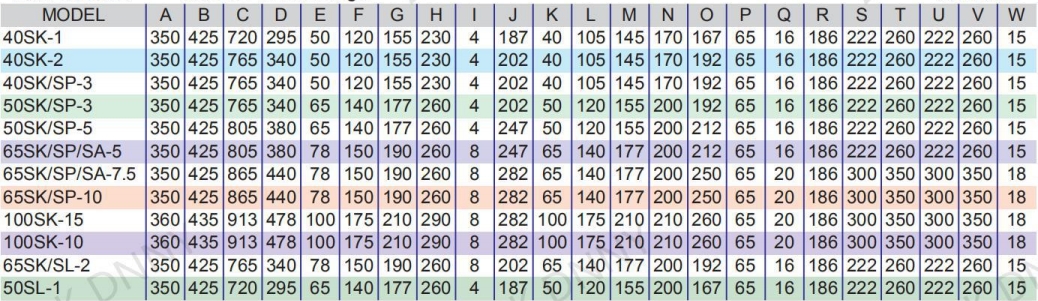

DIMENSION UMIT:MM

While placing your order...

Please kindly provide us the following information.

While placing your order...

Please kindly provide us the following information.

1. Chemical: Name/Concentration/Temperature/Specific gravity/Viscosity.

2. Capacity needed:__________L/min

3. Head needed:__________M

4. Power: Voltage/Frequency